90% WNiMoFe Tungsten Alloy for Extrusion Dies

90% WNiMoFe tungsten alloy is ideal for dies in the extrusion of metals, evaluation test of the two die material below will show you clearly.

H-Test of H-13 die steel

An H-13 die set was run to failure to establish a base line and to gain experience in die casting copper. To minimize thermal shock with the first few shots of molten copper, the dies and shot sleeve were preheated to about 350°C with an oxyacetylene torch. As expected, substantial physical damage was quickly evident after only about 20 shots. The run was continued for a total of 750 shots during which steady deterioration by heat checking, cracking and erosion at insert joints and ejector holes was taking place. The run was discontinued when ejection of the casting became difficult as copper solidified in the deep fissures. Electrical conductivity of the die-cast copper averaged 98% IACS.

Test of 90% WNiMoFe tungsten alloy

Take 90% WNiMoFe tungsten alloy for instance. 90% WNiMoFe tungsten alloy is tungsten base containing 4% Ni, 2% Fe and 4% Mo. The alloys were tested simultaneously in the test die. The die material investigated, the first heated die configuration had been designed and installed on the machine. This allowed preheating and maintaining the dies at 450°C. This was the maximum temperature attainable with this initial heater array design and was about 100°C below the minimum required to avoid exceeding the yield strength at the surface suggested by the thermal modeling. Failure of one or more heaters during the first run of 500 shots resulted in operation at an even lower temperature for a portion of the run. Despite these problems, no heat checking of either alloy was evident but minor cracking of the anviloy inserts at sharp radii was noted.

So, with sufficient preheat and maintenance of the operating temperature at 550°C, it is obvious that 90% WNiMoFe tungsten alloy is a suitable die material for die casting of pure copper. High base material and machining costs are deterrents to its use, but anviloy may offer a viable alternative in a part or parts of the die, such as the runner or gate, where the incoming metal temperature or flow rate are extreme.

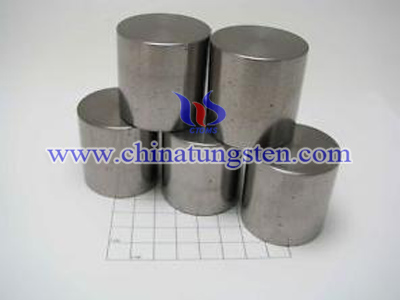

We can supply 90% WNiMoFe tungsten alloy in shape of rod, plate, block and finished parts according to the user's drawing.