90WMoNiFe Tungsten Alloy for High Performance Moulds and Dies

90WMoNiFe tungsten alloy are commonly used in cooling inserts, wear resistance inserts, sprue bushes and sprue posts. Compared to steel, high performance moulds and dies made by 90WMoNiFe has following characteristic and advantages:

90WMoNiFe tungsten alloy factors:

1.High resistance

2.High hardness

3.High strength

4.Good thermal conductivity

5.Good tempering resistance

6.Can form separation layers

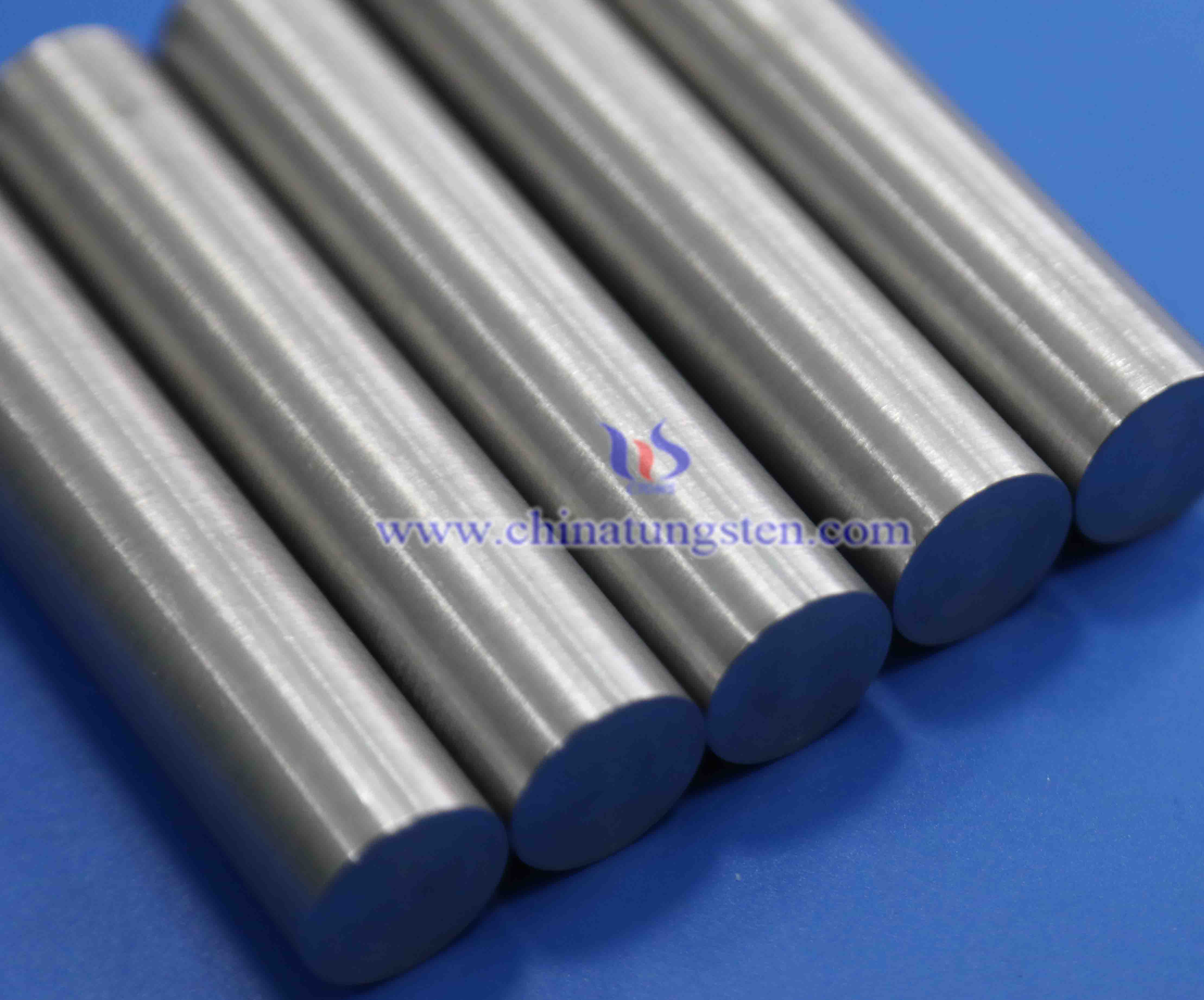

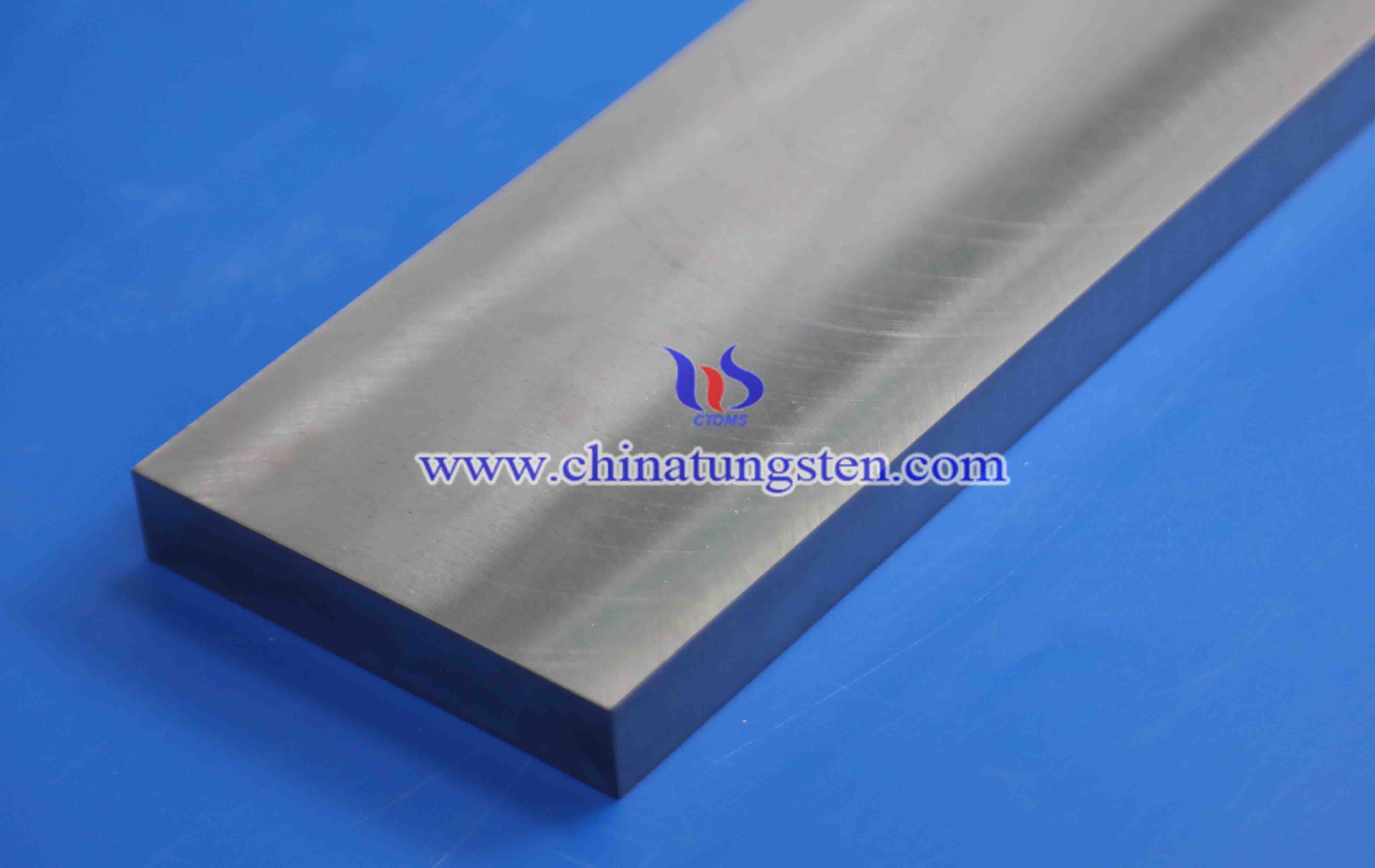

7.Easy to machine into various shapes

90WMoNiFe tungsten alloy advantages:

1.Reduces corrosion and erosion

2.Increases form stability

3.Improves stability of dimensions

4.Removes heat quickly

5.Minimizes heat checks

6.Reduces soldering

7.Various shapes possible

8. Longer Lifetime of Dies and Molds