90% WNiMoFe Tungsten Alloy

90% WNiMoFe tungsten alloy is tungsten-bearing sintered alloy of high density and high strength. It is a PM product and one of a series of alloys with densities 50% greater than that of lead. It is is a material developed specifically for its high-temperature strength and excellent thermal conductivity which provides an additional benefit to increase cooling in difficult to cool areas and thus potentially increases die casting production rates. It is used to best advantage in place of lower-conductivity, high-temperature tool steels. Simplicity of tooling manufacture with no heat treatment, low erosion, and excellent resistance to thermal cracking make it a premium choice for applications where H-13 and similar grades have been used in die casting.

With 90% WNiMoFe tungsten alloy for your tools ,you will be pleasantly surprised with longer core and die life, and the product surface are more smoothly without porosity in heavy section, besides, cost has been down as less production down time and you will happy about fewer rejects.

Due to tungsten's high melting point and low coefficient of thermal expansion, tungsten is used as a base for 90% WNiMoFe tungsten alloy. Elements added to the tungsten enhance machinability and ductility. The table below shows components and properties of 90% WNiMoFe tungsten alloy 1150 both in Metric and English.

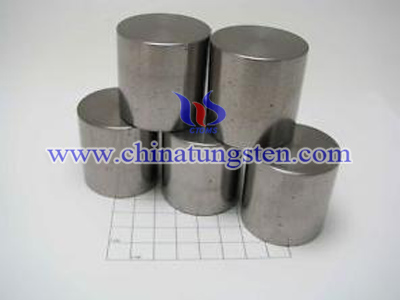

The product is a high density, tungsten-based material produced by powder metallurgy techniques. 90% WNiMoFe tungsten alloy is widely used in the hot extrusion dies, die casting tooling, and high mass and gyro.

We can supply 90% WNiMoFe tungsten alloy in shape of rod, plate, block and finished parts according to the user's drawing.